Food Safety, Reducing Waste and Improving Profitability

Food Safety, Reducing Waste and Improving Profitability

An Industry Survey

Part of Food Marketing & Technology’s commitment to bringing the latest news and updates to our readers, and the industry in general. is to keep a finger on the pulse of major topics and the latest trends. In recent months we asked selected readers in Germany and Great Britain for their help in a project focusing on optimizing food operations to help manufacturers reduce food waste and improve profitability. The project consisted of a series of questions about various industry specific themes such as traceability and aspects of food safety. Correct lubrication of machinery was also a topic. The questions were sent out to approximately 7000 readers by email, post and as a insert in the current issue of Food Marketing & Technology. The responses were collected and analyzed by our team in house and the results are presented below.

The first question asked whether readers expect the EU food production legislation to tighten its farm-to-fork traceability standards in the light of recent food scandals. Over 83% thought yes, this was important, with only 3% expecting no change at all.

Answers to the second question were even more clear, with more than Food Safety, Reducing Waste and Improving Profitability 89% of respondents believing that consumers are becoming increasingly more interested in where their food comes from. However the question as to whether concerns about safety and sustainability will translate into purchase behavior were less conclusive. Still, over half the answers (56%) suggested that they would have an effect. Interesting too that more than one fifth (22%) felt that although people are concerned, this would not play a role in food choices. Even today, where consumers seem to study food labels more than ever before, there is still an industry perspective than consumers are often confused by labels and food claims.

Questioned as to the responsibility for safeguarding food safety, 69% of our readers agreed that food operators should accept this responsibility rather than relying on industrial trade bodies to police standards, although 20% found that regulatory associations should apply more pressure.

Almost all food manufacturers questioned believe that they should offer full supply chain traceability for their produce, with over 94% claiming it is “quite” or “very” important.

We also asked the readers about food lubricants and their role in food safety. The need for food grade, NSF H1, lubricants in high-value high-margin markets in Europe were accepted by 59% of the respondents. A further 28% considered this important but not yet widespread.

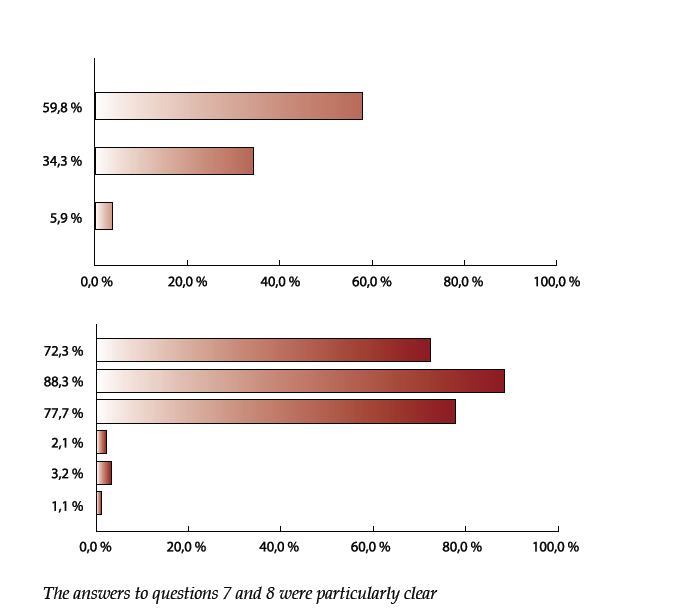

Asked whether implementing costly traceability/safety assurance programs means that food manufacturers have to sacrifice processing efficiencies, leading to a possible revenue loss, brought a mixed response. 60% agreed with the statement, but over a third thought that there were other cost-effective ways to uphold food safety.

Taking this point further, we asked what safety measures are in place to prevent and identify the presence of pathogens, contaminants or allergens in food products. The most important measure was to work only with trusted and certified suppliers (88%), to conduct regular processing chain audits throughout the food chain (78%) and to use food grade lubricants (72%). Using blue-prints from regulatory authorities only drew 3% of the answers.

Asked about the most effective ways to reduce food waste, the answers were again mixed. By far the most effective way of reducing waste was suggested as finding new ways to reuse waste through innovations (81%). Also of interest (62%) was the use of lubricants to prevent large-scale waste caused by contamination and recall. Over half the replies (55%) suggested using supply chain tracking to ensure quality control. If we consider the weightings of answers in the order of importance, there was also a lot of interest in improving the cold chain to improve right from on-farm losses. More practically speaking, over 10% of respondents suggested using small pack sizes as an effective way of reducing food wastage, which was not one of the original options.

Following on from the cooling and cold storage issue, question 11 asked what the most important factors were in finding the right solutions. The biggest problem seems to be one of reliability (88%), followed by energy efficiency benefits (72%) and performance (63%). Training and maintenance also featured highly in the weighted results.

Moving back to industrial lubricants, 5% of respondents admitted to having incidental contact with food products in the past five years, although only 46% were sure they had not. When asked about improving their critical food processing equipment, cold storage and/or refrigeration performance, five options were offered. 84% were ready to take a proactive approach to maintenance, whilst 72% ranked an increase in monitoring the equipment in second place. 58% and 57% respectively favored running the equipment with OEM recommendations and upgrading to higher quality lubricants. Less than half (43%) were ready to purchase new equipment.

Having accepted the importance of lubrication, the final question asked the questionees to rank the important criteria when selecting it. In the number of answers, 71% placed NSF H1 registration as the most important, with OEM recommendations second (61%) and energy efficiency benefits third (59%). Interesting to note that NSF H1 registration was mostly placed second or third by the responders, with the other answers inconsistently being top and further down the rankings.

It is clear that European food industry professionals take the issues of food safety and waste very seriously, possibly as a result of the recent scandals. Most seem to take a mature and common sense approach, avoiding panic reactions, whilst at the same time revisiting their own situation honestly. It is also good to see that traceability – from farm-to fork – is a realistic strategy. Food grade lubrication has a big role to play in this scenario, from both a postive, quality and maintenance standpoint, as well as helping to avoid waste and spoilage. To conclude this research we talked with Rainer Lange, Mobil SHC brand advisor, EAME, ExxonMobil Fuels & Lubricants for his input.

Mr. Lange you have seen the survey results. Is this what you at expected? “If we start with questions 1-3 then yes, I have to say we expected to hear that legislation and consumers are becoming more interested in increased food safety and traceability. It is also clear that increased quality will increase purchasing power. The results for question 4 are also exactly as we expected. It is good to see companies being proactive in taking responsibility and initiatives. The food industry is based on trust more than any other, so we are greatly encouraged by this.

“Exxon Mobil can support traceability and food safety by offering suitable food grade lubricants. These branded products can offer potential energy efficiency benefits, help extend oil drain intervals and significantly boost productivity, all of which improve profit margins. This is reflected in the answers seen here. NSF certification is growing even more in importance.

“The answers to no 7 show a certain lack of awareness of the true benefits of the right lubricants. Increasing efficiency leads to increasing safety and reducing energy demands. The actual cost of lubricants is a very small part of the maintenance budget, but the difference in lubricant quality can make a very big difference. Food scandals destroy the trust which has been built up and which often takes a long time to get back. Food manufacturers need to take more responsibility themselves and it is good to see that reflected in the answer to question 4 here.

“The results to question 11 also tally with our findings. Cooling and cold storage equipment has to work; this has a major effect in reducing food waste – and lubrication has a big part to play here. “Increased monitoring and equipment protection cannot be overemphasized.

After all, we take good care of our personal health, so why not the health of our machinery. Exxon Mobil has worked closely with OEMs for over 100 years, to find the right oils. Customers in the food industry tend to rely on the OEM recommendations. Again, it is a question of building trust between the individual links of the chain.

“Advancing machine performance and productivity, as well as taking care of the environment, are all logical steps which have the end result of helping the food manufacturer to reach his own goals. If Exxon Mobil can play a part in this process, we have reached our own goals.”

For more information on lubricants, visit www.oil.ie