Hydraulic Fluid Shear Stability

Â

Â

Machinery and the lubricants that protect them are often exposed to a wide variety of ambient and operating temperatures. As a result, lubricants are often required to maintain good pumpability at low temperatures and sufficient film strength at high temperatures. Prime examples are hydraulic fluids used in industrial and mobile equipment applications that operate in a wide range of environments and temperatures. It is not difficult to find a lubricant to meet these requirements, but there can be performance concerns is the fluid is not properly formulated. Fluids with a wide operating temperature range are often formulated with special viscosity improver additives to improve both high and low temperature viscometrics and these additives are subject to shearing forces that can reduce their effectiveness in service.

The Viscosity temperature relationship

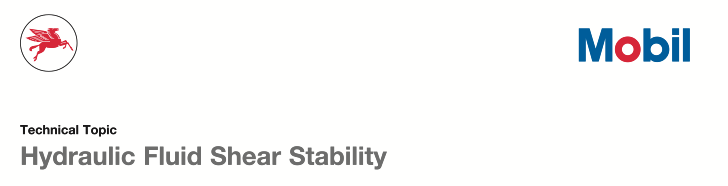

The viscosity of lubricants changes with temperature. As temperature rises, viscosity decreases, and as temperature decreases, viscosity increases. A measure of the relative rate of change of viscosity with temperature is referred to as the fluid’s Viscosity Index or VI.

Viscosity Index is an empirical, unit-less number used to quantify the change od viscosity with respect to temperature. The viscosity of a fluid with high VI does not change as rapidly with temperature when compared with a lower VI fluid. For mineral hydraulic fluids, typical VI is between 90 and 110.Â

Â

Viscosity Index Improvers

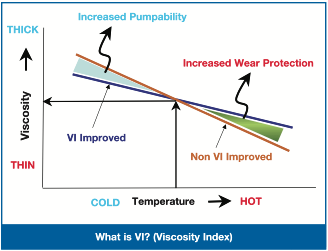

The VI of a fluid can be enhanced through the use of specialized additives called Viscosity Index Improvers. These additives are typically high molecular weight polymers designed to minimize temperature’s impact on viscosity. VI improvers swell with increasing temperature, which counteracts the decreasing viscosity of the base fluid. This results in a fluid that maintains sufficient oil film thickness at high temperatures. At lower temperatures, VI improvers shrink and the properties of the base oil dominate the viscosity of the fluid.Â

Shear Stability Measurements

There are three commonly used methods for determining the shear stability of a high VI fluid.

DIN 51382 – The Bosch Injector Test is considered to be the least severe of these methods. The test oil is run through 250 cycles at 2550 psi and the change in viscosity is measured.

ASTM D5621 – The Sonic Shear method functions by shearing the sample hydraulic fluid in a sonic oscillator for 40 minutes and the change in viscosity is measured. The test is favored by some USA OEMs, but is increasingly being replaced by the CEC L45-A-99 KRL Tapered Roller Bearing Test.

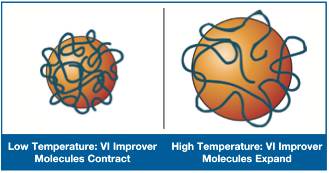

CEC L45-A-99 – The KRL Tapered Roller Bearing test is becoming the test of choice of many OEMs around the world and it is considered the most severe and offers the best correlation to actual field performance. The test oil is run in a fitted tapered roller bearing for 20 hours under the design load. Before and after the viscosities are compared for percent viscosity loss.

The graph below shows a 12.6% reduction in viscosity shear loss from a shear unstable oil to a shear stable oil as tested in the KRL Tapered Roller Bearing test.

Shear Stability Application Testing: Hydraulic Pumps

While laboratory tests provide useful data on shear stability of hydraulic fluids, another method is to measure shear stability in an operating hydraulic pump. Testing in a hydraulic pump replicates the forces and conditions encountered in everyday use. In the example below, data was collected from two fluids in a Vickers 25 VQ Vane Pump test rig run at 138 bar (2000 psi) and 52°C for 168 hours.Â

Â

.png)

In this example, the shear unstable high VI hydraulic fluid suffered a nearly 30% viscosity loss in just two days and falls out of the ISO viscosity grade in less than one day of pump operation. On the other hand, a more shear stable formulation retains consistent viscosity for the duration of the test. The differentiation has a significant implication in the lubrication and operation of a critical hydraulic system.

Â

Impact of Shear Stability: Temperature Operating Window (TOW) and “Afternoon Fade”

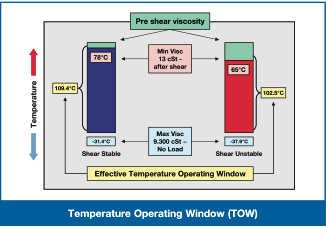

Excessive permanent shear, as shown above, has serious implications for a hydraulic system. As shear increases, the fluid’s Temperature Operating Window (TOW) decreases.

The TOW of a hydraulic fluid is a measure of the minimum and maximum temperature operating range. A hydraulic fluid’s TOW is dependent on initial viscosity and its VI. The effective TOW seen in the field is also impacted by shear stability as illustrated below, where a shear stable fluid has a broader TOW than a less shear stable fluid of higher VI.

Increasing shear reduces the high temperature properties of the fluid by lowering the viscosity. As an example, consider the two fluids used in the pump test. The equipment OEM recommends an ISO VG 46 hydraulic fluid for the expected operating temperatures. Based on the vane pump rig testing, within one day’s time, the shear unstable ISO VG 32; in less than two days, the oil has even dropped out of ISO VG 32 grade. This loss in viscosity would likely increase wear during elevated temperature operation, which could lead to equipment failure.

Additionally, the lower viscosity could result in what many operators refer to as “afternoon fade”. Increasing system and ambient temperatures commonly occur as a machine works late into the day. When the temperature rises, viscosity decreases and the volumetric efficiency of the system pumps diminishes. The result is a reduction of volume output from the pumps, slowing the response speed of the actuators in the system. Fluids with a high amount of shear loss may experience proportionately more “afternoon fade” compared to fluids that have higher shear stabilities, ultimately reducing the productivity of the machine.

Conclusion

The ability of a hydraulic oil to maintain optimum viscosity under a wide temperature operating window can be achieved with a shear sable, high VI, hydraulic fluid. Well formulated, shear stable, high VI hydraulic fluids have been tested to maintain optimum lubricant viscosity maintaining a wide temperature operating window and preventing a decrease in volumetric efficiency.

Â

Â