Interpreting Oil Analysis Results

29 August 2015

Industrial

From time-to-time, I am asked why sudden changes in the physical or chemical properties of lubricating oil or wear metals in oil samples, evident in used oil analysis reports, may occur. Let me share some insights on this topic.

Often, when operators receive “normal” results in used oil analysis reports, they think it’s a sign that they are “good-to-go” and simply save the results and move on. Of course receiving “normal” results is great news, but it serves no purpose if operators pass over the opportunity to take a closer look at the results. Â Â Â

It’s important to remember that the true purpose of a comprehensive oil analysis program is to provide ongoing insights into lubricant and equipment performance. This allows data trends to be thoroughly analyzed and, done right, can help operators identify potential areas of concern for key equipment at the earliest stages, when potential corrective actions will be most impactful.

Thus, receiving normal results and filing them away without proper review can cause operators to miss the opportunity to distill some insight into the operation of applications at their facility. An effective oil analysis program can help monitor the oil ÃÂs physical and chemical properties over time, as well as metal wearing. Paying attention to “normal” analysis results is necessary for identifying in advance when abnormal conditions arise and understanding that such conditions could lead to premature component damage or even catastrophic failures if not addressed in time.

When you receive normal results, you should take a moment to compare the results to the previous report to identify any changes in the physical and chemical conditions of the oil.

For example, if your comparison shows an increase in oil viscosity, it could signify that the system has started to run at higher temperatures than normal or that the application is overloaded, even if the increase in oil viscosity has not yet reached the limit for your application The reason for this change in viscosity can vary, but in order to prevent further damage, the change needs to be identified and corrected as soon as possible.

Similar situations can occur with regard to wear metals. For example, if you notice higher values of copper in your oil analysis results, along with a change in the oil viscosity, you might want to review the machine cooling system to monitor pipe condition, search for loose fittings, and identify any unwarranted vibrations.

Some of the most common abnormal conditions that tend to arise include diesel engines that show increased levels of silicon and iron, but fail to reach alarming levels during oil analysis; or perhaps, when hydraulic oil analysis results show an increase in water and copper, which can serve as a pre-cursor for a future pump or valve failure.

So, when reviewing results from routine oil analysis, if you see a “sudden” increase in any value, it could be caused by some oversight in the findings of previous oil analysis results.

Will that always be the case? No. We will still need to consider that many external factors can lead to unexpected damage. However, following a disciplined oil analysis program can help to anticipate situations that will help make operational failures the exception, not the rule.

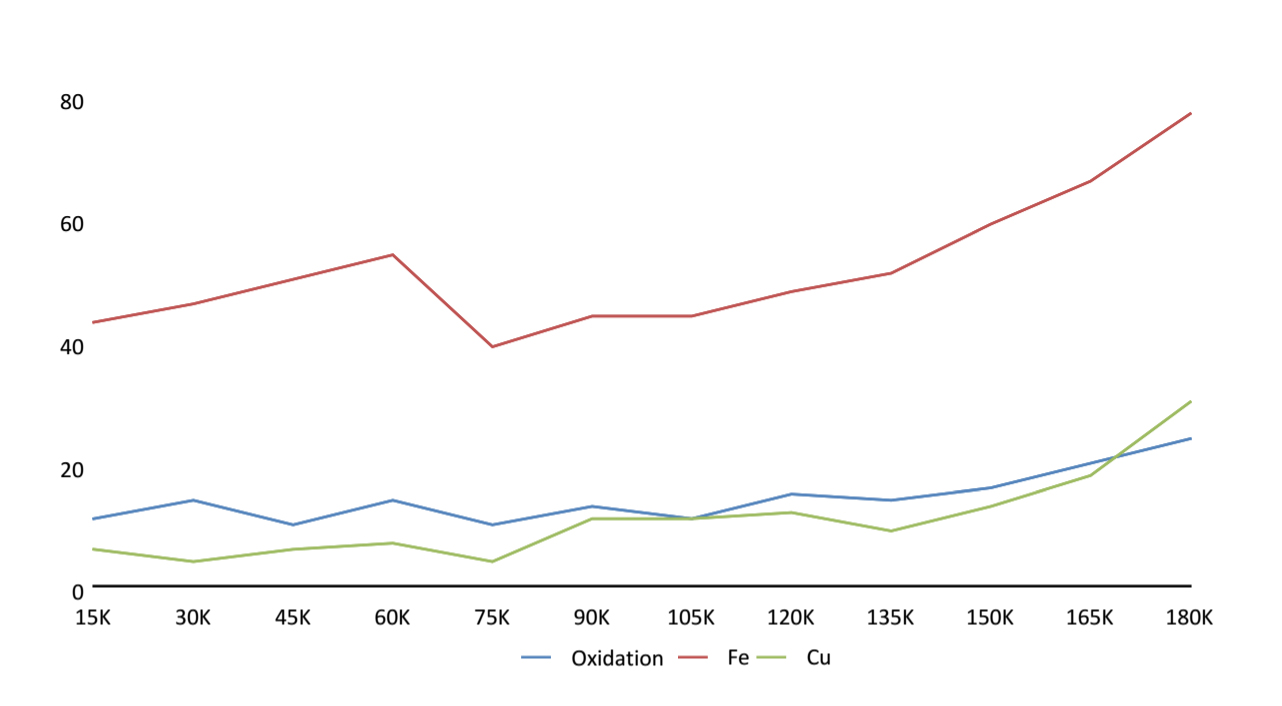

Caption: This figure shows an example of how data reflecting Oxidation, Iron (Fe) and Copper (Cu) values in a diesel engine can maintain normal levels over thousands of kilometers, but, at a certain point, the values can begin to grow. Such a change indicates that something is happening in the engine that is causing altered results, even though none of the indicators have yet reached the point at which they would trigger an “alert” flag.

Â