Mobil Pegasusâ¢1005 improves productivity while lowering costs

Situation:

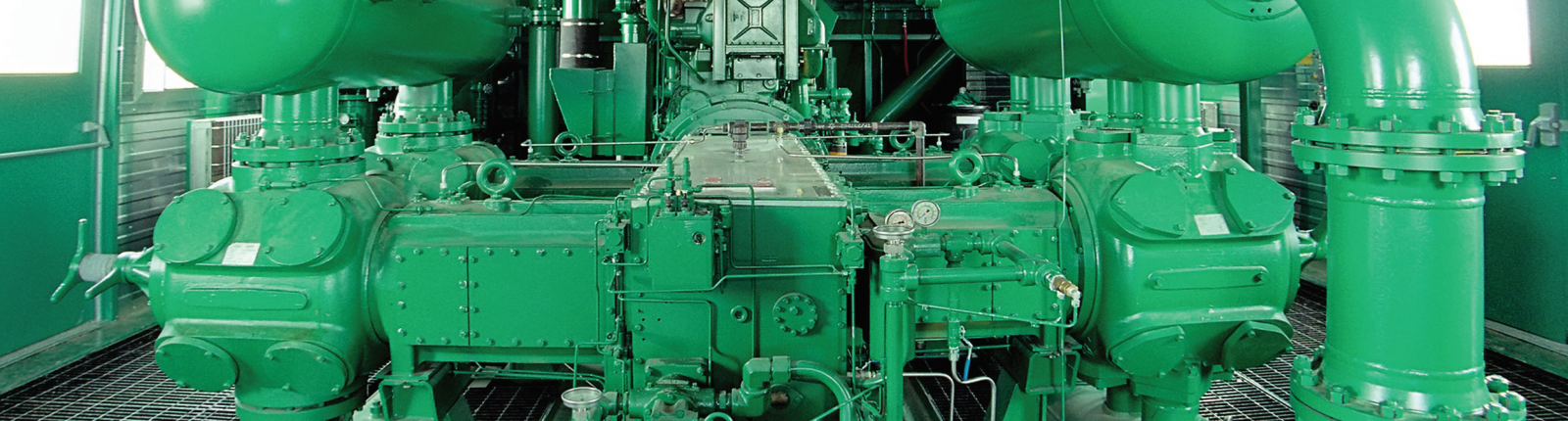

A French power plant was operating three Cummins QSK 60 gas engines in cogeneration mode for a five-month period, using natural gas to

produce electricity and steam.  To optimize production and reduce maintenance costs through longer drain intervals, the company switched from

a conventional mineral oil to Mobil Pegasus™ 1005.

Â

Solution:

Â

Â

By making that switch, the company reduced the number of oil changes during the season from three to one, which helped reduce the cost of labor

while increasing uptime and production of the gas engines. In used-oil analysis, Mobil Pegasus 1005 demonstrated retention of its properties after

1,800 hours. Its performance saves €4,899 on these engines per season.

while increasing uptime and production of the gas engines. In used-oil analysis, Mobil Pegasus 1005 demonstrated retention of its properties after

1,800 hours. Its performance saves €4,899 on these engines per season.

Â

Â

Â

Â

The above Proof of Performance is based on the experiences of an individual ExxonMobil customer. Actual results can vary depending upon the type of equipments that are used, their maintenance, operating conditions, environment, and any prior lubricant used.Â

Â

To find out more contact your local Burke Lubricants Representative so that you can learn how certain Mobil-branded lubricants may provide benefits to help reduce environmental impact. Actual benefits will depend upon product selected, operating conditions and applications

Â

Â

Â

Â

Â